In the world of engineering, manufacturing and geology there exists several methods for identifying material hardness. Some test methods are typically used for metals; others are for minerals. Various “experts” will try and tell you that certain hardness measurements are to be used ONLY for certain materials. However, while perhaps typically used by a specific field, there are some cross-reference tables that show a reliable comparison between one type of material hardness scale with another.

For steel and various metals Brinell and Rockwell tests are typically performed. I’ve conducted Rockwell tests with regards to heat treating and annealing tool steel as a Tool-and-Die/Machinist apprentice at GE many years ago. In the world of minerals and stone there is the Mohs scale of hardness.

Summary of Test Methods

From a broad materials hardness perspective there are essentially three different types of methods for measuring it: Scratch, Indentation and Rebound.

- Indentation (material deformation due to a constant compression load from a sharp object): Brinell, Rockwell, Vickers, Shore, Knoop

- Rebound (diamond-tipped hammer dropped on a material): Leeb & Bennett (basically a variation of indentation testing)

- Scratch (measure of how resistant a sample is to fracture, scratch or deformation due to friction from a sharp object): Mohs

Indentation and Rebound are primarily used on metals. Mohs is used on minerals and stone.

For this website’s purpose I will refer to the Mohs scale of hardness; specifically as it applies to stone working discussions (i.e. which material can cut/shape/sculpt another material, and which can’t).

What is the Mohs Scale?

This system of material hardness testing was created by Friedrich Mohs in 1812, although the methodology is claimed to have been first mentioned by Theophrastus in 300 BC, and Pliny the Elder in 77 AD. It measures the relative scratch resistance of a mineral via the ability of a harder material to scratch a softer material. The observer scratches a mineral surface with either: a kit containing reference minerals, or metal point tool kit (scratch picks) as shown here. The picks are easier and more accurate in their use.

The hardness of a material is determined by observing whether its surface is scratched by one of those substances of known or defined hardness. If the material can be scratched by a 7 but not by a 6, then it falls on the Mohs scale as 6-7. The scale is composed of ten reference minerals that have been given arbitrary values from 1 -10. (1 is very soft; 10 is very hard)

Here is the standard table of the relative Mohs hardness scale for minerals:

| Mineral | Mohs Hardness (relative) |

|---|---|

| Talc | 1 |

| Gypsum | 2 |

| Calcite | 3 |

| Fluorite | 4 |

| Apatite | 5 |

| Orthoclase feldspar | 6 |

| Quartz | 7 |

| Topaz | 8 |

| Corundum | 9 |

| Diamond | 10 |

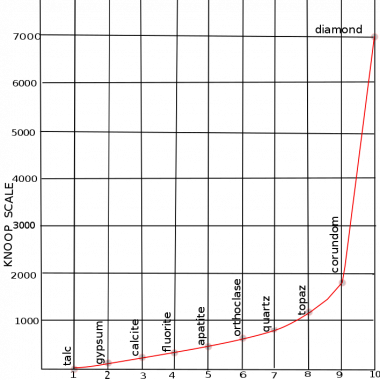

This scale is relative – – NOT linear and therefore not proportional. The movement from 3 to 4 on the scale is an increase of hardness by about 25%. However, the movement from 9 to 10 on the scale is an increase of hardness by about 300%. It becomes more exponential (from a graphical representation) at the harder end of the graph. The two graphs below display this in a more impactful way – showing the Mohs relative scale along the bottom and the Knoop (left-hand graph) & Vickers (right-hand graph) absolute scale vertically. You should now see that the absolute scale shoots way up after about Mohs 6 or 7.

(Attribution: Eurico Zimbres, CC BY-SA 2.5 via Wikipedia Commons)

While mineralogists will perhaps balk at using Mohs for stone hardness, their protests are fairly empty and lacking. A scratch hardness test – whether on a mineral or a stone (igneous, metamorphic, sedimentary) – will still measure a relative ability of one type of earthen material to scratch/cut another – based on hardness. For example, as noted on the Wikipedia page for Mohs Scale, Topaz-rich Granite is between 6 and 7 on the Mohs scale, however it’s made up of numerous minerals such as: Topaz (8 Mohs), Quartz (7 Mohs), Orthoclase Feldspar (6 Mohs), Plagioclase Feldspar (6 to 6.5 Mohs), Mica (2 to 4 Mohs). In this example it’s obvious that the vast majority of the minerals contained in the Granite are 6 to 7, so the net result should be a default of 6 to 7. Why is the doubt even present?

Interestingly many of the graphical representations show comparisons to non-mineral items such as a fingernail (2.5), copper coin (3.5), knife/glass (5.5), steel nail (6.5), and a masonry drill bit (8.5). So…arguing that it can’t be used to as a comparison to other materials is a moot point. The scale itself now references materials outside of minerals alone.

After extensive research, here’s a table of comparison in the Mohs scale of hardness for a variety of stones as they compare to various metals mentioned as cutting tools:

(I update this table as more data is discovered)

| Material | Mohs Hardness (Relative) | Knoop Hardness (Absolute) |

|---|---|---|

| Talc | 1 | N/A |

| Tin, Lead | 1 - 1.5 | ? |

| Limestone (porous) | 1.7 - 2.6 | ? |

| Gypsum | 2 | 50 |

| Alabaster | 2 - 3 | ? |

| Gold, Silver | 2.5 - 3 | 90-200 |

| Copper | 3 | 120 |

| Calcite | 3 | 135 |

| Copper (hammered) | 3.25 - 3.75 | 150 - 200 |

| Bronze | 3.5 | 175 |

| Platinum | 3.5 - 4.0 | ? |

| Limestone (dense) | 4 | 150 |

| Fluorite | 4 | 165 |

| Iron, Nickel | 4 - 4.5 | ? |

| Cast Iron | 4 - 5 | ? |

| Marble | 4 + | 200 - 500 |

| Apatite | 5 | 360 - 430 |

| Diorite | 5 - 6.5 | ? |

| Dolerite | 5 - 6.5 | ? |

| Sandstone (Nubian) | 5 - 8 | ? |

| Copper, Beryllium (alloy) | 5.5 | 460 |

| Steel | 5.5 - 7 | 460 - 800 |

| Orthoclase Feldspar | 6 | 560 |

| Titanium | 6 | ? |

| Andesite | 6 - 7 | ? |

| Granite | 6 - 8 | 550 - 650 |

| Quartzite | 6 - 8 | ? |

| Basalt | 6 - 8 | ? |

| Hardened Steel | 6.5 - 8 | 700 - 1000 |

| Quartz | 7 | 710 - 820 |

| Tungsten Steel | 7 - 7.5 | ? |

| Topaz | 8 | 1190 - 1250 |

| Aluminum Oxide [abrasive] | 8 - 9 | 2000 - 2050 |

| Chromium Steel | 8.5 | ? |

| Tungsten Carbide Steel | 8.5 - 9 | 2050 - 2150 |

| Corundum | 9 | 2200 |

| Corborundum (Silicone Carbide) [abrasive] | 9 - 10 | 2150 - 2950 |

| Boron Carbide [abrasive] | 9 - 10 | 2900 - 3900 |

| Diamond (synthetic) | 10 | 6000 - 7500 |

| Diamond | 10 | 8000 - 8500 |

Several years ago I created the following graph for a presentation I made to the Louisville Esoteric Society (on Megalithic Anachronisms). I overlaid the graph to also include the Mohs value ranges for various stones (in blue text) and metals (in red text). The point of this is to show that in order to cut/shape/carve/sculpt stone of a certain hardness you need to use a tool that is harder – whether a harder stone tool or harder metal tool. A softer material cannot cut and sculpt a material that is harder.

Therefore the argument that precision statues and building stones made of sandstone, diorite, andesite, granite, basalt, quartzite, dolerite could have been precisely cut & carved using copper or bronze; well – – it simply cannot be done. This is the critical element to keep in mind when looking at the flimsy theories held by orthodox academics who claim otherwise.

Online Resources:

- Geology.com – Mohs Hardness Scale

- US National Park Services

- Wikipedia: Mohs Scale

- Wikipedia: Hardness

- Britannica: Mohs Hardness

- Hardness Conversion Chart (does not include Mohs) – but is a good cross-reference for the other scales

Featured image by CARLOSCRUZ ARTEGRAFIA via Pexels License

Fair Use Notice:

– In good faith, this work contains fair use of copyrighted and non-copyrighted images from the public domain & the web for non-commercial & nonprofit educational purposes.

– This work is distributed free of charge.

– The author has neither monetized this work nor sought any profit from its distribution.

– Copyright disclaimer under section 107 of the copyright act 1976: Allowance is made for “Fair Use” for purposes such as criticism, comment, news reporting, teaching, scholarship, and research. Fair use is a use permitted by copyright statutes that might otherwise be infringing. non-profit, educational or personal use tips the balance in favor of fair use.

– This work contains original work of commentary and critical analysis.